A colleague of mine once asked a plant manager how their CI programme was going and was amused at the reply – “Oh the CI programme? We finished that a couple of years back”

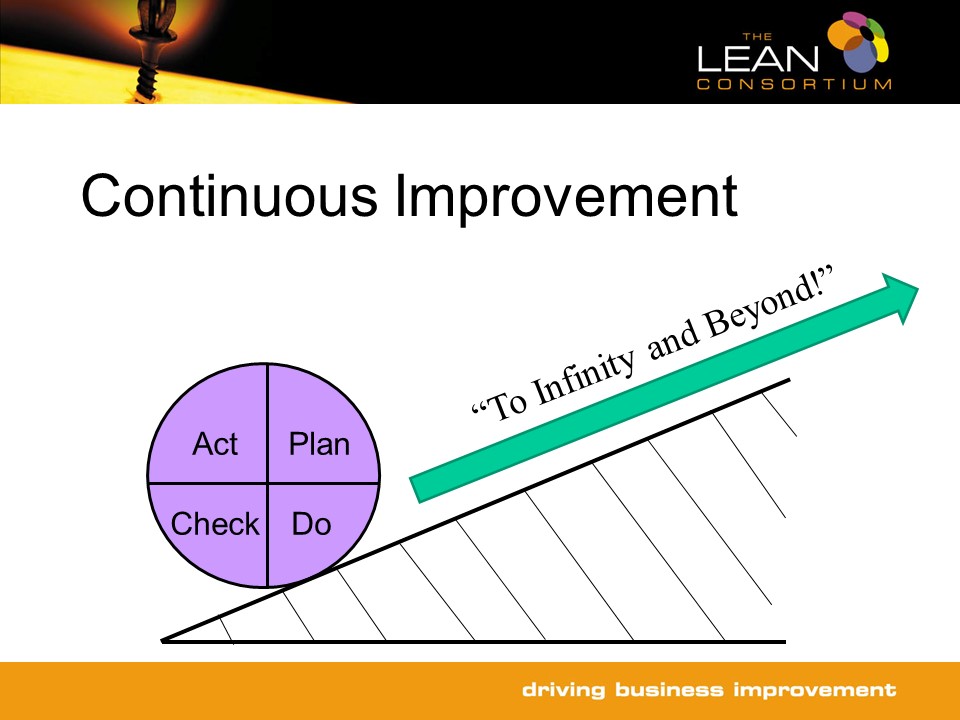

Joking aside though, it’s sometimes tempting to think that our Lean / CI “journey” should continue forever – a relentless, unending pursuit of unattainable perfection. But is that true?

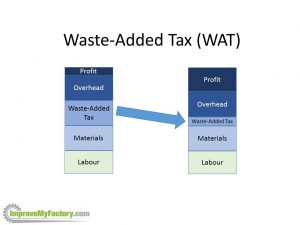

Back in the 1980’s, one of the many newly discovered concepts from Japan was this idea of constantly pursuing perfection – “Chasing the last grain of rice” became a well-known phrase in business. I was at Hewlett Packard at the time and like most of the managers there was running several TQM (Total Quality Management) projects. After several years of wholeheartedly buying into the TQM philosophy (aka “drinking the Kool-Aid”), senior managers began to question this philosophy and realised that “spending 10,000 dollars to solve a 500-dollar problem” didn’t make good business sense.

That’s one reason why I often remind people not to lose sight of two of the most important tools in the Improvement Toolbox – “Common Sense” and “Judgement”.

As in many aspects of life the answer to the question is: “It Depends”.

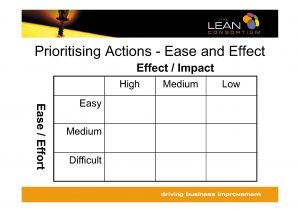

Along with Investment, Innovation and Improvement are the lifeblood for any business wanting to survive and prosper in the long term. Overall, we need to maintain a relentless focus on improvement but we also have to apply “business common sense”, and keep asking:

How likely is it that the benefits will justify the resources required?

Can we deliver the results in a reasonable timescale?

Are the outcomes / benefits we’ve achieved “good enough for now”

As part of your PDCA cycle it’s good practice to regularly review your improvement activities, check that they’re on target, and consider whether some of them should be “culled” to make way for better projects.

For help with managing your improvement activities, please contact Andrew.Nicholson@ImproveMyFactory.com