By Andy Nicholson, Managing Director of Nicholson Consultancy

In my previous blog I suggested that many organisations have come to understand that their future success requires the marshalling of Purpose, People and Processes, to deliver value to the organisation, its customers and its stakeholders.

So let’s look at what this actually means in practice:

The purpose of a Lean organisation is to create and deliver real long-term value.

The technical side of this requires a deep understanding of customers and stakeholders and should make clear exactly how, why, when and where value is added.

For the Purpose element to work a common set of values and a vision need to be drawn up that people feel are worthwhile and that they can get behind.

The truly Lean organisation values and develops its people, treats everyone with respect, and demands excellence.

To ensure sustainable continuous improvement requires, what W Edwards Deming, many years ago, described as “Constancy of Purpose” – the discipline of doing the important stuff day after day after day.

When it comes to People, the first and most important step is to get the right people on the bus – people whose values and attitudes fit with those of the organisation.

I’m with the approach of Jack Welch, as CEO of General Electric, on this one – if managers don’t demonstrate those values, they need to be replaced, regardless of how well they “hit the numbers”.

Lean organisations know how to recruit and retain people with the right values, and they are expert at developing each and every employee to their fullest potential.

Such organisations aim to engage people in a greater purpose, they recognise and reward their contribution, and they train and empower them to do the right thing in their own work-flow.

When Henry Ford talked about “the machine that God built” and Jim Womack, Dan Jones, and Dan Roos, wrote “The Machine that Changed the World” they weren’t talking about the motor car itself, they were talking about the process that created the motor car.

From the outset, Ford and Toyota understood that the myriad tasks and activities in a manufacturing plant should work together smoothly and effectively like a well-oiled machine.

Lean organisations are obsessed with their value streams – the essential value-adding tasks by which they create and deliver value.

They actively manage their extended value streams – their supply chains – by partnering and working with their suppliers and customers.

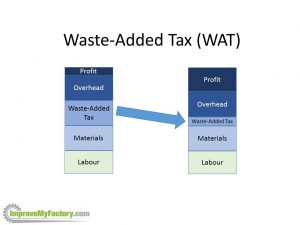

All the time, their people are working to understand “exactly how is value added, how do we cut out the waste, how do we link the pieces together and improve flow?” Put simply, good processes deliver good results.

Last, but not least, pulling all of this together requires the right leadership – leaders who have the right values, who are passionate about Lean and who are in it for the long haul: the sort of people who work very hard to make things very simple.