Back in 1999 Mike Rother and John Shook produced a guide to Value Stream Mapping, with the memorable title “Learning to See”. A more accurate title might have been “Learning to see manufacturing”, since manufacturing is where Value Stream Maps originated (at Toyota, like many of the Lean tools and techniques), and where they are most effective. For some years now people have been applying the Lean principles to many other non-manufacturing processes, with varying degrees of success. It’s not difficult to understand why…

The world of operations and manufacturing deals largely with tangible items – materials, components, products that we can physically see, count and touch. When we need to look instead at information we quickly realise that we’re in a very different world – one where data can move at the speed of light and exist in more than one place simulaneously. It’s a bit like moving from the world of conventional physics to the world of quantum physics. We need a different approach when we want to see information.

Before we do this, let’s take a step back and consider what it is that we’re trying to achieve…

The starting point for many improvement programmes is to understand exactly how the current process works. We need the people who carry out the process to map it – “process mapping”. The idea is to create a visual model – a “cartoon” – so that everyone can see and understand what is going on. When we get together the right team – from all parts of the process – to map out the current way of doing things (the “current state” or “as is” situation) and then to study the process in detail, it’s usually very obvious to them where the problems lie. Given the right tools – and some expert help, of course – they can then improve or “re-engineer” the process, to create the “future state” or “to be” situation.

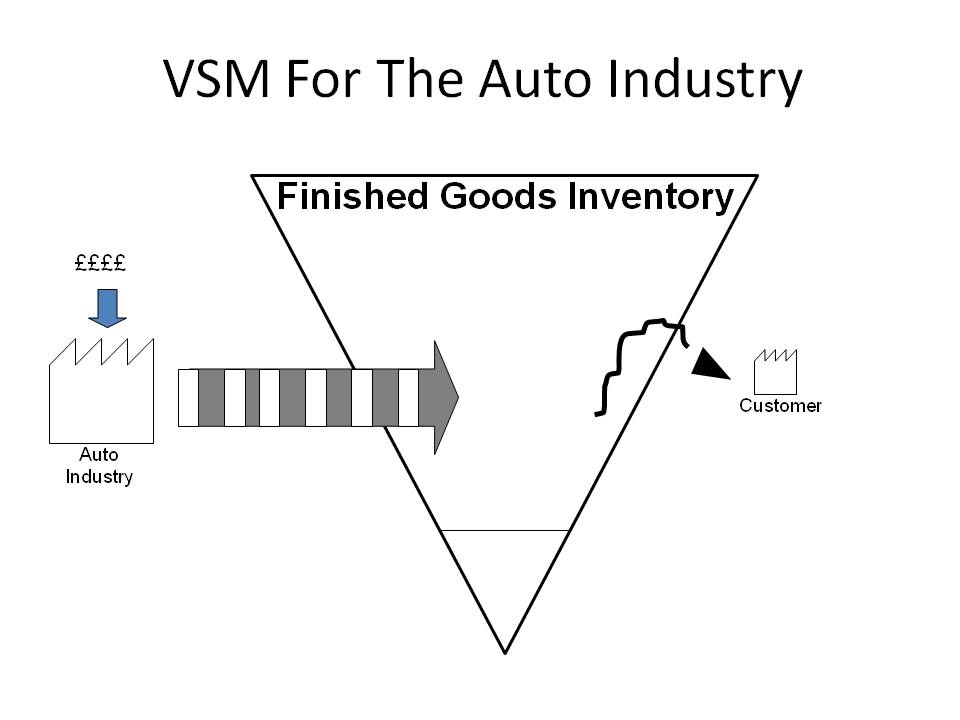

When it comes to manufacturing or other operations where we are processing tangible items – components, chemicals, food or other things that we can see, touch, count and measure – the preferred technique is Value Stream Mapping (VSM). VSM is a great tool to help the team visualise this type of operations. Unfortunately, it’s much less useful when it comes to the processing of information and data. We realise that we’re in a different world when we try to work with information – all of that intangible “stuff” that can move at the speed of light and be in more than one place at the same time. Then we realise that we’re using a hammer to drive a screw and that if we could find a screwdriver instead then maybe we’d find it a lot easier.

The first bit of good news is that the mapping tools are already out there, and have been for many years. They’re called Data Flow Diagrams (DFD’s). Put simply, people who work with products use Value Stream Maps and people who work with information use Data Flow Diagrams. The next bit of good news is that Data Flow Diagrams are much simpler and easier to use than Value Stream Maps. DFD’s can be drawn by using only four simple symbols.

So the next time you need to map out information-based processes, forget Value Stream Maps and instead use Data Flow Diagrams…