You’ve probably seen a number of “Ten Tips to Survive the Credit Crunch” articles recently, so instead let’s focus on what our most successful manufacturers are actually doing at the moment. You might not believe it if you watch the current TV news coverage but some of our clients are continuing to grow and to make money. They’re cutting costs in the short term but also investing for the upturn (which is when most business failures actually occur).

In no particular order, here are some areas to work on. If you’re already doing these -well done! If you’ve got some ideas of your own, please post them here. If they’re new to you – look and learn (remember: Plan-Do-Check-Act).

Demonstrate that you’re taking effective steps to manage through the downturn. Make it clear to everyone the two or three most important objectives over the next year and understand the benefits you will produce for your Customers, your Business and your employees (Cus, Bus, Us). For example – focus on reducing lead-times, eliminating waste (the Seven Wastes) and increasing value.

Take a cold, hard look at what will add value over the next 12 months. Get rid of anything that won’t (products, plant, premises or people) and do it now.

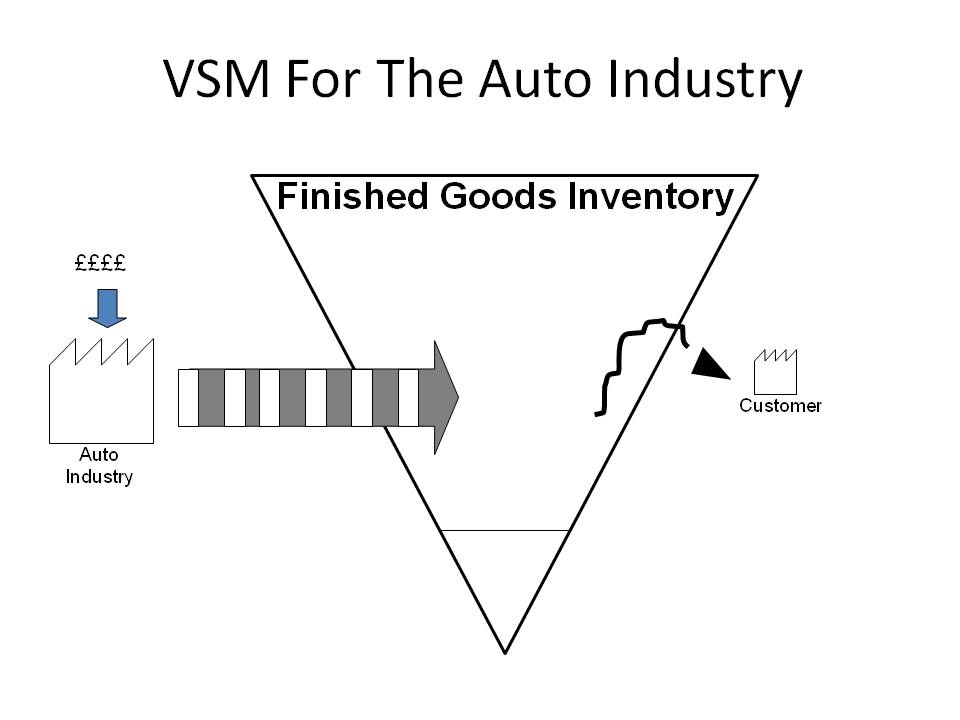

Cash is king and funding is hard or impossible to find. Free up cash by reducing your working capital – use Lean tools to reduce stock and work in process, slash lead-times and speed up your cash collection process. If you’ve got cash, pay suppliers promptly in return for reduced prices or extra value. If you haven’t, provide the same to your customers (see below).

Look at ways in which you can do more for your customers – if you can, preserve prices but offer more value (get more value into the product and provide the best service you possibly can). Get closer to your customers – go see them, understand their business and help them get better. Train them to understand your products better and to use them more effectively.

Use any spare time created to train people to perform better. Do this with a mix of new job skills (multi-skill the workforce if you haven’t already) and improvement skills. Make sure you’ve got an up to date skills matrix covering every single employee. Include all key skills. Specify how many people you need with each of those skills and identify the gaps. If you haven’t already, make sure that everyone understands the basics of Lean thinking, how to spot non-value-added activities and how to solve problems. Get free and/or subsidised training and support from national and/or local government schems (in the UK contact the Manufacturing Advisory Service www.mas.dti.gov.uk). Provide free training for your suppliers.

Get together with other manufacturers in your region to share the costs of training (www.leanconsortium.co.uk), logistics, support services.

Cut your costs and admin. overheads by streamlining all of your non-core purchasing (see www.fcprocurement.com). Glen Feechan of FC Procurement also has a blog which you may find of interest (see www.notjustnumbers.co.uk).

Most of all, stay positive, focus on those things that you can do and don’t worry about those that you can’t.

See you on the other side…