Congratulations to everyone at Analox for reaching the finals of the Orange Business of the Year Awards – well done!

Author Archives: Andrew Nicholson

“True Lean” Leadership – a tale of waste management, people and change

It’s incredibly rewarding when our Lean Leaders demonstrate by their actions that they really understand what improvement is all about. That they really “get it”. Yesterday I saw another great example of this at one of our clients – it’s what I call “True Lean” Leadership.

Chris was given the job of improving her plant’s environmental performance and achieving ISO14001 accreditation. She quickly identified waste management as the main priority. It caused lots of problems and cost a lot of money. She used “go see” – she tracked waste streams throughout the plant and she saw them all end up in the same skip / dumpster. Then she went and visited the company’s waste contractors. She took some of her colleagues. They watched as their waste skips were emptied out into the yard and a whole crew of people spent hours manually sorting the contents back into their different types. Waste in every sense of the word! Pretty clear that her colleagues needed to sort the waste streams at source and not mingle them all together.

Problem solved?

Of course not.

Why?

Because the changes meant getting people back at the plant to change the behaviours of a life-time.

So – she put together a presentation to explain to her co-workers why it was important, what they needed to do and – most importantly – what’s in it for them.

She presented this first to a whole room full of Lean experts during a best practice visit to another of our clients (who had just been shortlisted for the Factory of the Year Awards) – no pressure there!

She asked for comments and feedback.

She then acted on the feedback and changed her whole presentation.

Yesterday she showed her new presentation to her Plant Manager and me.

It was one of the simplest, clearest presentations I’ve ever seen (and I’ve seen – and delivered – thousands over the years). Straightforward, hard-hitting and persuasive.

Next week she’s delivering her presentation to every employee in the plant.

And then a whole load of people from the Factory of the Year plant are going to visit and she’s going to show them how to do it!

I’ll leave you to identify how many examples of effective Lean implementation you can pick up on here. How much of Chris’s approach can you apply in your own improvement activities?

And finally, I’ll leave you with a challenge – if you were Chris’s boss, how would you recognise her efforts and how could you help her to help her colleagues change their behaviours?

James Heal – SME Manufacturer of the Year

Congratulations to our client James H. Heal & Co. for winning the Yorkshire Post Excellence in Business Awards – SME Manufacturer of the Year, sponsored by the Manufacturing Advisory Service. Well done to all of the team!

http://www.yorkshirepost.co.uk/custompages/CustomPage.aspx?pageID=78916

Using Lean to Grow your Business – Part 2!

Saw a really good example of this at one of our clients earlier this week. Their Marketing Manager and Designer went out to vist a representative sample of their customers and end-users. They saw exactly how their products were used, met with the various people involved in specifiying, buying and using the product and asked loads of questions. They found out all sorts of useful information and loads of things that they can do to improve the product, better their competitors and do more business. As per the Kano model (see the earlier blog post) there were one or two “dissatisfiers” – little things that really anoyed the end-users. There were some simple changes that will improve the product and make the customer happier. We even brainstormed some ideas of how we could delight the customer. Over the next year this will undoubtedly lead to happier customers and more sales. It’s all about using the Lean approach to add more value for your customers and it’s a great win-win.

Lean Manufacturing in a recession – add value or eliminate waste?

Most manufacturers are aware of the basic idea of Lean Thinking – “add value and eliminate waste” – but too many focus on the “eliminate waste” side of the equation and lose sight of the “add value” opportunities. In fact, one of the biggest hidden wastes is “unfulfilled customer needs” and a recession is the best time to tackle it.

Unfortunately – as many of you will have experienced – there’s often little point in actually asking customers what they need. There are two main reasons for this:

- They don’t know what you could do for them. Henry Ford put it rather well – “If I’d have asked my customers what they wanted, they’d have wanted a faster horse!”.

- They don’t want to spend lots of their time and effort helping you to run your business better – they’ve enough work to do running their own business, thank you!

So you have to make the effort to make it easy for them – here are five pointers:

- Don’t expect them to take time out to complete lengthy questionnaires – I never do. Ask them first and, whenever you can, speak to them direct. When you do, try the following:

- Keep it brief. Keep it simple. It’s often better to know what 100 customers think about three things than what three customers think about 100 things.

- Offer them choices – if we can turn around your order in less than 48 hours, would that be worth having? Would a Ten-Year Gurantee be of use to you? Would it help if all of the tests were automated?

- Give them feedback – we’re planning to report on the survey results by the end of the month – would you like a copy?

- And – most important of all – act on what they tell you (then ask what they think and improve it again).

Let me know how you get on…

The Lean Office – Learning to see information with Data Flow Diagrams

Back in 1999 Mike Rother and John Shook produced a guide to Value Stream Mapping, with the memorable title “Learning to See”. A more accurate title might have been “Learning to see manufacturing”, since manufacturing is where Value Stream Maps originated (at Toyota, like many of the Lean tools and techniques), and where they are most effective. For some years now people have been applying the Lean principles to many other non-manufacturing processes, with varying degrees of success. It’s not difficult to understand why…

The world of operations and manufacturing deals largely with tangible items – materials, components, products that we can physically see, count and touch. When we need to look instead at information we quickly realise that we’re in a very different world – one where data can move at the speed of light and exist in more than one place simulaneously. It’s a bit like moving from the world of conventional physics to the world of quantum physics. We need a different approach when we want to see information.

Before we do this, let’s take a step back and consider what it is that we’re trying to achieve…

The starting point for many improvement programmes is to understand exactly how the current process works. We need the people who carry out the process to map it – “process mapping”. The idea is to create a visual model – a “cartoon” – so that everyone can see and understand what is going on. When we get together the right team – from all parts of the process – to map out the current way of doing things (the “current state” or “as is” situation) and then to study the process in detail, it’s usually very obvious to them where the problems lie. Given the right tools – and some expert help, of course – they can then improve or “re-engineer” the process, to create the “future state” or “to be” situation.

When it comes to manufacturing or other operations where we are processing tangible items – components, chemicals, food or other things that we can see, touch, count and measure – the preferred technique is Value Stream Mapping (VSM). VSM is a great tool to help the team visualise this type of operations. Unfortunately, it’s much less useful when it comes to the processing of information and data. We realise that we’re in a different world when we try to work with information – all of that intangible “stuff” that can move at the speed of light and be in more than one place at the same time. Then we realise that we’re using a hammer to drive a screw and that if we could find a screwdriver instead then maybe we’d find it a lot easier.

The first bit of good news is that the mapping tools are already out there, and have been for many years. They’re called Data Flow Diagrams (DFD’s). Put simply, people who work with products use Value Stream Maps and people who work with information use Data Flow Diagrams. The next bit of good news is that Data Flow Diagrams are much simpler and easier to use than Value Stream Maps. DFD’s can be drawn by using only four simple symbols.

So the next time you need to map out information-based processes, forget Value Stream Maps and instead use Data Flow Diagrams…

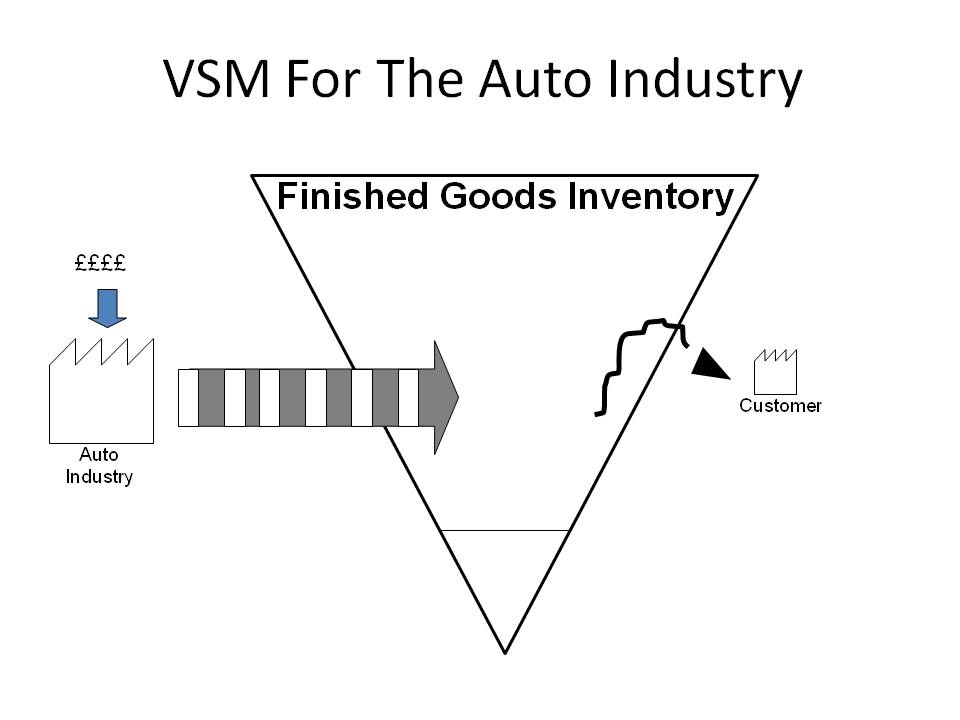

A Lean View of the Automotive Industry

Lean for tough times

You’ve probably seen a number of “Ten Tips to Survive the Credit Crunch” articles recently, so instead let’s focus on what our most successful manufacturers are actually doing at the moment. You might not believe it if you watch the current TV news coverage but some of our clients are continuing to grow and to make money. They’re cutting costs in the short term but also investing for the upturn (which is when most business failures actually occur).

In no particular order, here are some areas to work on. If you’re already doing these -well done! If you’ve got some ideas of your own, please post them here. If they’re new to you – look and learn (remember: Plan-Do-Check-Act).

Demonstrate that you’re taking effective steps to manage through the downturn. Make it clear to everyone the two or three most important objectives over the next year and understand the benefits you will produce for your Customers, your Business and your employees (Cus, Bus, Us). For example – focus on reducing lead-times, eliminating waste (the Seven Wastes) and increasing value.

Take a cold, hard look at what will add value over the next 12 months. Get rid of anything that won’t (products, plant, premises or people) and do it now.

Cash is king and funding is hard or impossible to find. Free up cash by reducing your working capital – use Lean tools to reduce stock and work in process, slash lead-times and speed up your cash collection process. If you’ve got cash, pay suppliers promptly in return for reduced prices or extra value. If you haven’t, provide the same to your customers (see below).

Look at ways in which you can do more for your customers – if you can, preserve prices but offer more value (get more value into the product and provide the best service you possibly can). Get closer to your customers – go see them, understand their business and help them get better. Train them to understand your products better and to use them more effectively.

Use any spare time created to train people to perform better. Do this with a mix of new job skills (multi-skill the workforce if you haven’t already) and improvement skills. Make sure you’ve got an up to date skills matrix covering every single employee. Include all key skills. Specify how many people you need with each of those skills and identify the gaps. If you haven’t already, make sure that everyone understands the basics of Lean thinking, how to spot non-value-added activities and how to solve problems. Get free and/or subsidised training and support from national and/or local government schems (in the UK contact the Manufacturing Advisory Service www.mas.dti.gov.uk). Provide free training for your suppliers.

Get together with other manufacturers in your region to share the costs of training (www.leanconsortium.co.uk), logistics, support services.

Cut your costs and admin. overheads by streamlining all of your non-core purchasing (see www.fcprocurement.com). Glen Feechan of FC Procurement also has a blog which you may find of interest (see www.notjustnumbers.co.uk).

Most of all, stay positive, focus on those things that you can do and don’t worry about those that you can’t.

See you on the other side…

Times Past, Present and Future

The New Year is a good time for reflection and review, for planning the year ahead and for resolving to improve. The time of year – and the title of this blog – Manufacturing Times – got me to thinking about the importance of time in a business. In many ways the squandering of time is one of the worst forms of waste – it’s invisible and once it’s gone we can never get it back. As manufacturers our approach to times – manufacturing times – has changed greatly over the last 20 or 30 years, and not always for the better, in my view.

I’m talking in particular about production times – the time that it takes to achieve a specific task or perform a value-adding operation.

I would argue that accurate times – or at least good estimates – are pretty much essential for a well-run manufacturing business. Why? Because they’re so fundamental – we need accurate times so that we can:

- Calculate the true cost of a product, so that we know the margin or contribution that each product creates

- Plan the loading of machines and people, so that we have the right capacity in the right place at the right time

- Establish a realistic production schedule, so that everyone knows what to make when

- Quote achievable and competitive lead-times, so that we attract and retain customers

- Measure performance, so that we know where we’re doing well and where we need to improve

Back in the early days of mass-production there was a great emphasis on Scientific Management, Work Study, Industrial Engineering and the like. With the advent of Lean Thinking, many manufacturers no longer have any effective means of establishing accuracte production times. This strikes me as particularly ironic since many of the great pioneers of Lean – including Taichi Ohno at Toyota – were first and foremost Industrial Engineers. Perhaps we no longer want to employ the armies of Work Study engineers that were once common in most manufacturing businesses but in my view it’s essential that we at least understand and apply the basic principles. In a future article we’ll consider exactly how to calculate Standard Times but for the moment let’s look at some of the basics:

Perhaps the most important point – and one that confuses many people – is that we need to establish a “standard” time for each operation. This should represent the time taken by a competent operator to perform the task at the maximum rate that can comfortably be sustained over the working day and working week. The word “Standard” is so important – Lean is all about setting standards, measuring and improving performance and following “One Best Way”. Employing a random group of individuals and having each of them do things in their own way and at their own speed and to their own level of competence might be the right approach for a group of creative professionals but in most production environments it’s often a recipe for poor performance, low morale and ineffective leadership. Let’s think first about how we should approach the task of establishing Standard Times:

- involve the people who work in the area that’s being measured – where possible, train them to do this

- start with the current “one best way” of performing each task

- wherever possible, assess a competent, trained operator

- take at least ten measurements of the time taken for each task (statistically, the accuracy of our results depends greatly on the number of measurements or observations that we take), and use the average (mean) of these

If you’re one of those many manufacturers who would benefit from more accurate production times, I hope that you’ll “resolve” to tackle this in the New Year and we very much look forward to hearing your comments and experiences …….

How to reduce lead-times

There are many reasons for wanting to cut lead-times, and many benefits when you do. Mostly it’s to do with competitive advantage. How long does it take your customer to obtain a similar product or service to yours, from a low-cost economy like China? If it’s 6-8 weeks you really don’t want to be taking longer than this! Help your customers to reduce their inventory costs and/or their own lead-times. Get really slick and transform your operations from Make to Stock to Make to Order!

You’ll improve customer service, reduce working capital (cash tied up), free up lots of space and get rid of lots of wasteful activities. It’s an area where Lean tools and techniques can make a huge difference very quickly.

So – how to do it:

First: map your process and measure the time taken for each activity. At its simplest, observe the process and simply list each activity. For more detail, use Value Stream Mapping. Distinguish between value-added tasks (those things that the customer will pay for) and non-value-added tasks (waste). Remember always to look out for The Seven Wastes (muda).

Calculate the total lead-time and the percentage of lead-time that is spent on value-added activities. It’s likely to be less than 5% in most manufacturing businesses. Next, look at where the non-value-added time is. Concentrate on the biggest time-wasters – often waiting time.

If you’re batching products, cut the batch sizes – just do it! Get back to the root causes for batching:

- If it’s because of set-up and change-over times then use set-up reduction techniques (SMED) to cut these.

- If it’s to make up for poor quality then get back to the root causes, inspect at source then apply mistake-proofing techniques and aim for zero inspection.

- If it’s to make up for machine breakdowns then start measuring OEE (Overall Equipment Effectiveness), train operators in basic maintenance, annalyse the major causes of downtime and brainstorm improvements.

As with all improvement activities use the Improvement Cycle: Plan-Do-Check-Act. Work out what you want to improve, how and why. Make the improvements then review the effect. Work out how to do it better next time. Do it better and do it again. Keep going!

Most of all – train the people, work as a team, measure the results, recognise those who contribute, and sell the benefits to your customers and employees.

… and start now!